Assessing our impact: the carbon footprint of MIRUM®

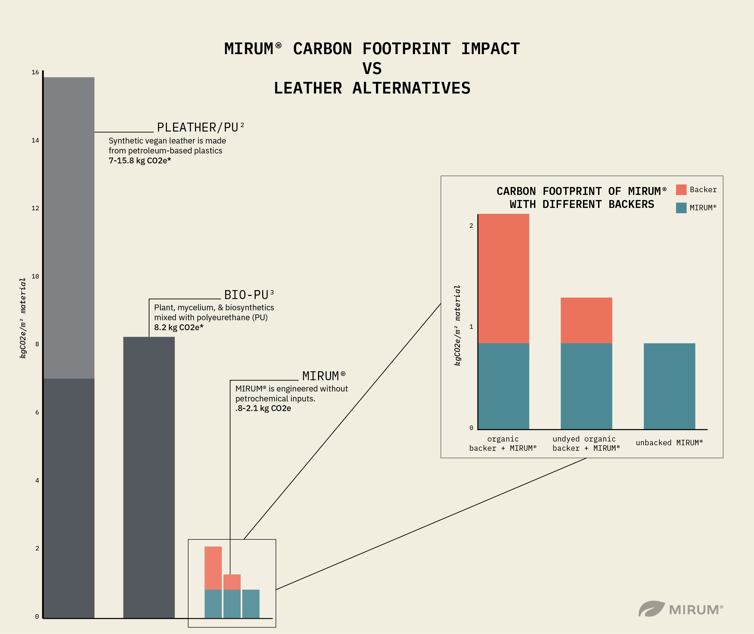

Initial assessments estimate MIRUM® produces around an order of magnitude less greenhouse gas emissions than synthetic leather-like materials and conventional chrome-tanned leather. MIRUM’s industry leading numbers are set to improve substantially as efficient production scales up further. If you're wondering how this is possible, keep reading!

Fashion is a major contributor to many urgent global issues. Unfair labor practices, overproduction, unsuitable production materials and methods, and waste all make it nearly impossible to buy shoes, clothing, and accessories without contributing in substantial ways to environmental degradation, climate change, and social exploitation. At the core of this material crisis: crude oil–derived plastic materials that cannot be truly circular. Fashion’s reliance on fossil fuels to make textiles, foams, and pleathers needs to change. Many “new” alternative materials, heralded as the answer to our material crisis, are hiding the use of high-footprint plastics such as polyurethane (PU) and bio-polyurethane (bio-PU) that come from and/or require petrochemical refinery technologies.

NFW is on a mission to initiate meaningful global-scale change by creating shockingly sustainable materials from the abundance of photosynthetic plants. For us, finding ways to reimagine and reinvent the materials that surround us is key to implementing positive change for people, planet, and animals. Our vision is to leave the world better than we found it. We are accomplishing this by scaling disruptive, highly efficient manufacturing that circumvents the vast and invasive petrochemical refinery system. Instead, we mix, mold and shape plants and other abundant natural materials (e.g., clay) directly into high performance materials like MIRUM. Plants, Not Plastic® sums up NFW’s ethos and overall approach.

To achieve our goals, it’s crucial that we holistically understand and honestly measure our impact. NFW believes in the broadest interpretation of “impact.” Today, impact assessment tools such as Higg MSI willfully exclude end of life impacts while keeping key data hidden as trade secrets. We believe this is a colossal mistake that makes it impossible to honestly approach the task of holistically reducing impact. Because the underlying assumptions are scientifically inconsistent, incomplete, or wrong, the process is flawed from the start. NFW is working with industry leaders on quantifiable metrics on issues ranging from biodiversity, inequality, pollution (elimination of toxic microplastic pollution), accessibility, and carbon emissions, just to name a few. More holistic assessments are on the way.

In the meantime, the following report specifically overviews how we measured, calculated, and analyzed the carbon emissions associated with the production of MIRUM. We also look at how that number stacks up against alternative materials. We will strongly caveat, however, that LCAs are not great for direct head-to-head comparisons unless a comparative-specific LCA is done. Even then, comparative LCAs can be prohibitively expensive and liable to the same issues that afflict other LCAs. Our founder and CEO, Dr. Luke Haverhals, is fond of saying, “LCAs are best described as frameworks for structured discussions.” As such, LCAs are only as good and useful as the frameworks that define what is “in” and “out” of scope. Moreover, even with a well-defined set of boundary conditions, LCAs are only as good and useful as the underlying data that are fed into the chosen framework. For example, there is increasing evidence that the greenhouse gas emissions of the petrochemical extraction and processing system are vastly underestimated in the databases that make up LCAs. Methane emissions from fossil resource extraction and water use associated with fracking are good examples of impacts that presently are underrepresented in published LCAs. Many of the figures that constitute the underlying data of LCAs are hotly contested across multiple industries. Simply put, LCAs are snapshots at a point in history limited by the scientific understanding and the accuracy of the data they use. LCAs are useful as starting points for sustainability conversations. NFW believes that only with rigorous ongoing discussion will it be possible for humanity to collaboratively solve the correct problems.

This is our first attempt to measure and discuss our findings on our material’s global warming potential (GWP). (GWP is typically measured in terms of CO2e, or carbon dioxide equivalence.) In the future, numbers will improve as we refine our methodologies and processes. This is one of our first steps towards scaling positive change. Due to the intrinsic efficiency and scalability of NFW production systems, we believe that our technologies will redirect fashion from its present disastrous path, towards a new path as a force for good that actively works to solve global problems and inequities. Thank you for joining us on this journey.

How we measured the impact of MIRUM

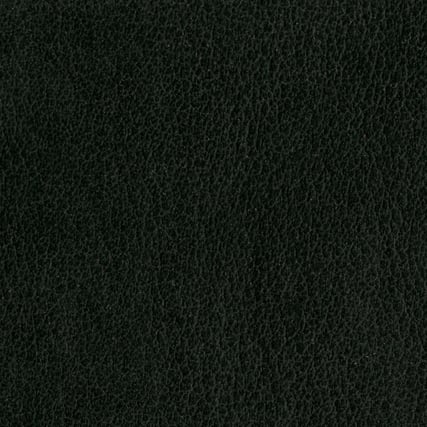

In early 2021, together with environmental consulting group Anthesis, we started our journey of continual life cycle assessment (LCA), working to understand carbon impacts along the MIRUM value chain. The assessment we conducted focused specifically on black MIRUM from the Signature Collection on an organic cotton backer, one of our best sellers. Our impact shows a range to consider the different ways in which our customers use this family of nutrient-based materials.

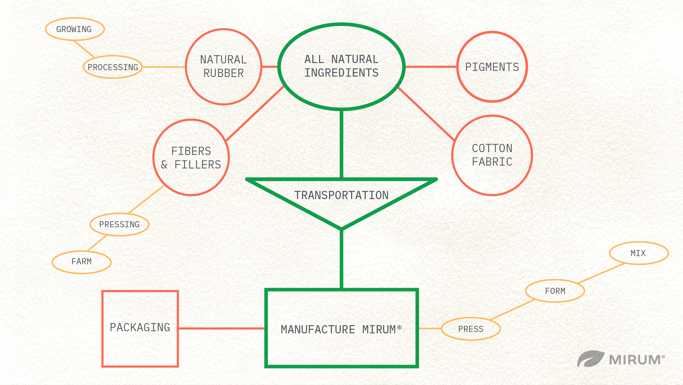

(Top: A swatch of MIRUM in black from the Signature Collection. Bottom: a diagram illustrating the construction of MIRUM material and a fabric backer.)

Applying methods consistent with the ISO 14040 series, we assessed the GWP of MIRUM beginning with the cultivation, processing, and transportation of our raw ingredients, and ending with the manufacturing and packaging of the material at our facilities in Peoria, IL. Using global datasets like GaBi and Ecoinvent, we calculated the emissions that come from each of our processed ingredients, transportation emissions, and our production machinery’s electrical energy usage while being used to produce MIRUM.

Presently, there are two common ways to measure CO2e: with and without biogenic carbon. Biogenic carbon emissions take into account plants’ photosynthetic processes that convert atmospheric CO2 into biomass like roots, shoots, stems, sap, and leaves. This atmospheric carbon-turned biomass then gets embodied into ingredients entering the material flow of the LCA, and is counted as a negative emission in the overall calculation. Non-biogenic carbon accounting omits this critical process from the picture. By ignoring the reality of natural carbon cycles, non-biogenic calculations favor plastic materials that use already “sequestered” terrestrial carbon (oil) instead of natural photosynthetic inputs. While the carbon that is stored in MIRUM will eventually biodegrade and be converted back into CO2, in the process it will contribute to soil organic matter and carbon storage and help stimulate the soil microbial community and plant growth. For these reasons, we believe biogenic calculations most holistically depict the carbon cycle in a given calculation, and so we decided to report using biogenic and non-biogenic calculations. This being said, biogenic carbon reporting is not standard in consumer goods that last less than 100 years. It is most commonly used in highly durable projects such as buildings (e.g. log cabins).

We outline the boundaries of our study because understanding the scope of an impact assessment is critical for any subsequent comparative discussion. For example, had we decided to measure the environmental impact starting when the raw ingredients had already arrived at our facilities (commonly done by some manufacturers), rather than including the impact of the growing, harvesting, and transporting of the ingredients themselves, we would have vastly different results. Omitting these data would certainly make NFW and MIRUM appear better, but lack of transparency surrounding scope would make it confusing when trying to compare results.

The plastic industry is rife with this sort of issue, which we refer to as “hidden cradle,” because information about the “cradle,” or the beginning of a material, is not openly shared. For instance, much LCA data used for plastics or fossil fuel based materials in the fashion industry is secretive about what data is used for the extraction of the raw material, and thus obfuscates the true impact of plastics. Consider how critiques of agricultural materials would change if where food comes from were “out of scope” in LCAs. Yet this is how analyses of plastics are often conducted and communicated. When the industry fails to account for the damage caused by fossil resource (or any resource) extraction, this creates a skewed perspective on the true impact of plastics. To us, creating as holistic a picture as we can is important. Unfortunately, details about the scope of studies are often left out, glossed over, or obscured. This is often the case with many “bio-plastic” materials that either digest biomass into petrochemical replacements or mix biomass with plastics of various types and sources. Conscious consumers should be on the lookout for transparency on scope.

MIRUM’s first carbon footprint assessment: 0.84-2.1 kg CO2e

After adding up all of the steps in our process, Anthesis’ assessment found that production of MIRUM results in emissions ranging from 2.1 (incl. Biogenic) to 4.9 (excl. Biogenic) kg CO2e per 1 kg of material. To put that amount of MIRUM into perspective, a one kilogram sheet is approximately 1.2 mm thick and approximately 1 meter squared. How much is 2.1 kg of CO2e really? For context, burning 1 L of gasoline produces approximately 2.3 kg of CO2. By this analysis, one square meter of MIRUM produces roughly the same amount of greenhouse gasses as driving 5 miles in an average passenger vehicle in the United States, or washing and drying one load of laundry. This study has shown NFW how we can improve as we scale such that our already low impact approach gets even lower.

Initial assessments estimate MIRUM produces around an order of magnitude less greenhouse gas emissions than synthetic leather-like materials and conventional chrome-tanned leather.

How does MIRUM’s footprint stack up to other materials like leather, synthetic “vegan” leather, and plant/plastic hybrids? MIRUM does extremely well, however, this is tougher to directly compare given the technical differentiation behind different materials and the associated choices of LCA boundary conditions. It is important to note here that we did not do an ISO-14044 compliant comparative assertion. We found a range of numbers in different studies for leather and leather-like alternative materials. The general trends show that MIRUM offers significant improvements over incumbent materials, perhaps by three to ten times worth of improvement! Why? Simply put, MIRUM is produced with low impact ingredients that are efficiently mixed, molded and shaped directly into materials that perform. NFW’s patented production systems are categorically unique and directly produce materials from abundant biomass, no plastics. Nature Reformatted® is, we believe, the most efficient system that can scale to everyone.

Again, it’s important to note that making comparisons between LCAs can be difficult because the scope and data sets used are not always consistent between studies. While ISO standards are applied to the methods for how an assessment is conducted, the databases used are typically generalizations and rely on secondary data that may not reflect specific supply chains, may not be appropriate at larger scale production, and do not always include equal levels of detail for inputs or system boundaries.1 Moreover, input data and boundary conditions often obfuscate instead of clarify; there are many ways in which LCAs for fossil fuel–based materials do not account for oil spills, methane leaks, water use/pollution, or land use change. Nevertheless, appropriately caveated comparisons are important to contextualize results. In an effort to be fair and transparent, we have included a range of numbers and included our references.

Making MIRUM: The Secret Behind our Low Carbon Footprint

The low carbon footprint of MIRUM is a testament to NFW’s comprehensive approach to scalable, all-natural and circular solutions. Throughout our three-stage process, we have made decisions to optimize our impact in ways that result in our low number.

It all begins with ingredient selection. At NFW, our materials start natural and stay natural, lowering their impact on the environment from start to finish. MIRUM is made with natural nutrient and bioneutral ingredients, never plastics or petrochemicals. This allows us to completely circumvent negative impacts such as microplastics. Utilizing plant inputs allows us to support the positive benefits of agriculture. By utilizing regenerative farming practices we can help sink carbon by building healthy soil through photosynthesis.

After ingredients are selected, we mix and form our ingredients into MIRUM that our brand partners use to make bags, shoes, automotive interiors, and more. These mixing and forming steps are done in our facility in Peoria, Illinois. If you want to learn more details about how MIRUM is made, check out this blog. We are proud to say that 100% of our electrical energy is offset through Renewable Energy Credits (RECs). Using renewable energy is key to reducing impact now, and for as long as the sun shines and the wind blows. The MIRUM manufacturing process does not require additional water inputs besides what is represented in the natural ingredients. This means there is no effluent (wastewater) discharge generated from the making of MIRUM. Due to the rapidly evolving process of making MIRUM, our manufacturing calculations had limitations. To determine the impacts that come from manufacturing, we calculated the energy requirements of our machines to produce MIRUM. However, not included are our associated facility energy usage, such as heating, lighting, or cooling the building - which contains both development and production equipment and personnel. Once we have more data compiled that we can draw from, we will update our number to better reflect the energy overhead required to produce MIRUM.

Lastly, we impart texture and mold the MIRUM composite face material onto the optional fabric backer in a single step. MIRUM is a complex natural composite material made from complex natural materials.

There are huge efficiency gains to be made globally and throughout the fashion, automotive, and upholstery industries. Across these consumer product industries, material inputs often make up the bulk of carbon contributions. NFW’s low-emission natural material alternatives are the solution to help brands create products that have a better impact on environments, in part through dramatic reductions of greenhouse gas emissions, but also more holistically by supporting regenerative agriculture practices, avoiding toxic plastic pollution, and creating new opportunities for a natural circular economy.

Looking Ahead

As this is our first impact assessment, consider this only the first of many discussions to come. Engaging in this formal process has taught us a lot about defining and measuring impact, and has given us many ideas on how we can improve our material as well as be a force for good, educating others about holistic assessment and practice. In the future, we will look to improve the fidelity, breadth, and accuracy of our data. We also aim to incorporate more study standards, and utilize relevant product category frameworks to make our study more comparable.

Carbon reporting is not a silver bullet to completely understand the environmental impact of a material choice or technology. Diffuse, but real environmental problems of plastics such as micro-plastic pollution, unaccounted methane emissions from fossil resource extraction, leaching of chemicals and toxins from petrochemical plasticizers and curative accelerants should be given appropriate weight alongside LCA carbon studies. Studying biodiversity, water use, and eutrophication (just to name a few) are also essential to build a holistic picture of how MIRUM affects our planet. In addition, the social impacts of a material absolutely cannot be ignored. The manufacturing of products has, for too long, been exploitative and opaque in nature, and in order to have a truly “sustainable” product, the people and the land must be treated with dignity and respect. NFW is uncompromising in our approach to be a force for good in these areas as well. We are committed to taking a continuous quality improvement approach to our sustainability practices, and impact assessments must be used in concert with certifications, audits, real-life relationships, and progressive policies in order to ensure positive results. We will talk more about what tools can be used to ensure fair and mutually abundant outcomes in future posts.

To solve the right problems requires full technical transparency and honesty about what are and are not comprehensively and holistically “good” ideas. This is the ONLY way to live up to our desire to be truly “good”, not merely another “less bad” player in the global materials economy. Our ideas and practices are sharpened through an open and collaborative dialogue. If these principles seem right to you, then please do consider reaching out to help NFW continue to bend human history for outcomes that benefit people, animals, and the planet we share.

References & notes:

|

Material |

kgCO2e / m^2 material |

Reference |

Scope |

|---|---|---|---|

|

MIRUM |

2.1 - 4.9 |

Anthesis 2021* |

Cradle-to-gate |

|

Synthetic leather |

7 - 15.8 |

UNIDO, 2017 |

Cradle-to-gate |

|

Biobased PU leather |

8.2 |

Locker et al., 2018* |

Cradle-to-gate |

|

Chrome-tanned leather, after slaughterhouse |

8.3 - 29 |

UNIDO, 2017 Notarnicola et al., 2011 Locker et al., 2018* |

Cradle-to-gate (excl. farming) |

*These numbers include biogenic CO2 removal. Part or all the carbon removed from the atmosphere will be released eventually at end-of-life, which is not included here. Assuming similar end-of-life conditions, the carbon in fossil-based materials will also be released at end-of-life.

1 For example, the reports cited give kgCO2e numbers in terms of a meter-squared of material, but do not provide thickness and/or density data for the material. Without that information, it is difficult to make a comparison that is exactly equivalent to our data. We therefore assume, in the data presented, a thickness of 1.2 mm (which is the higher side for MIRUM) for each material for ease of comparison, but numbers may change slightly if the thickness of the other material was known, or density and thickness was reported and used to convert to kgCO2e per kg material. Given NFW is assuming a higher thickness for our materials, MIRUM numbers may well be even better on a relative basis.

van der Meer, Y. 2018. FibreNet | Life Cycle Assessment: Benefits and limitations. FibreNet. http://fibrenet.eu/index.php?id=blog-post-eleven (accessed 28 February 2022).

Moni, S.M., R. Mahmud, K. High, and M. Carbajales‐Dale. 2020. Life cycle assessment of emerging technologies: A review. Journal of Industrial Ecology 24(1): 52–63. doi: 10.1111/jiec.12965.

2 Synthetic leather

Rebecca Locker, Ranjani Theregowda, Life-cycle assessment of Bioleather1, Cleaner and Circular Bioeconomy, Volume 1, 2022, 100003, ISSN 2772-8013, https://doi.org/10.1016/j.clcb.2022.100003.

Study Indicates INSQIN’s PU Is a More Sustainable Option. RIS News. https://risnews.com/study-indicates-insqins-pu-more-sustainable-option.

UNIDO. 2017. Leather Carbon Footprint Review of the European Standard EN 16887:2017. United Nations Industrial Development Organization.

3 Bio-PU

Rebecca Locker, Ranjani Theregowda, Life-cycle assessment of Bioleather1, Cleaner and Circular Bioeconomy, Volume 1, 2022, 100003, ISSN 2772-8013, https://doi.org/10.1016/j.clcb.2022.100003.

Chrome-tanned leather

Rebecca Locker, Ranjani Theregowda, Life-cycle assessment of Bioleather1, Cleaner and Circular Bioeconomy, Volume 1, 2022, 100003, ISSN 2772-8013, https://doi.org/10.1016/j.clcb.2022.100003.

UNIDO. 2017. Leather Carbon Footprint Review of the European Standard EN 16887:2017. United Nations Industrial Development Organization.

.png?width=1920&height=1081&name=04112022-C02_Blog_Tunnel_Vision_1.02%20(1).png)